1. Water Energy Nexus

I. INDUSTRIAL BEST PRACTICES

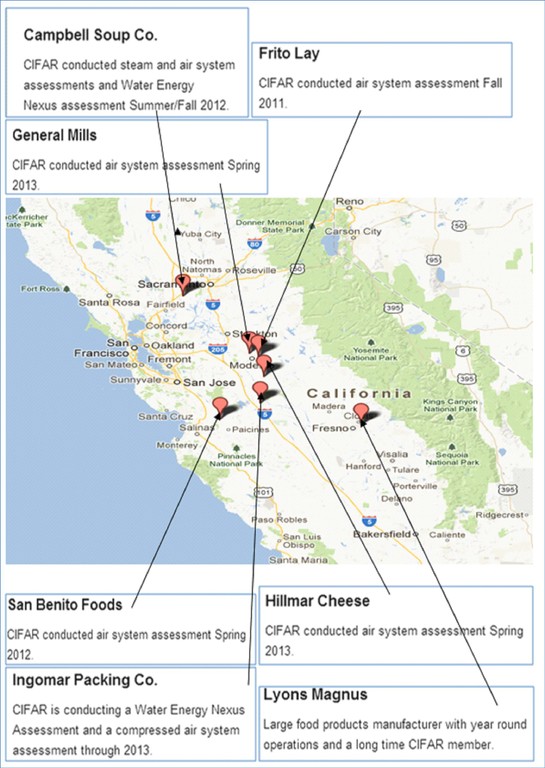

CIFAR’s staff, associates and sub-contractors offer field experience working in the operations and management of food and beverage processing facilities. They uniquely couple this experience with an ability to assess efficiency in industrial water and energy systems. CIFAR has leveraged these capabilities to design and implement resource conservation demonstration projects and perform economic assessments of existing and emerging technology investments. CIFAR utilizes the data collection protocols and software tools developed by the US Department of Energy (DOE) Industrial Best Practices (BP) program.

California’s Food Industry: Compressed Air Challenge

This report documents the results from Compressed Air Energy System Assessments (ESAs) conducted by Department of Energy (DOE) Qualified Specialists at eight California food and beverage processing facilities. The Qualified Specialists utilize the national Compressed Air Challenge (CAC) standards to collect data, evaluate the performance of compressed air systems and identify industrial Best Practices (BPs). The CAC created and established a national standard to support instructional curricula, technical support methodologies and evaluation software tools.

Campbell Soup Steam System Assessment

This report provides results from a Steam Energy System Assessment (ESA) conducted by DOE Qualified Specialists during the summer of 2012. The DOE’s ESA whole systems approach includes data collection and analysis of the steam system’s generation, distribution, end-use and recovery assets. This report supports research conducted by the California Institute of Food and Agricultural Research (CIFAR) at the University of California, Davis. CIFAR created and established an industrial Water Energy Nexus (WEN) methodology to calculate the water energy intensity of a California tomato processing facility.

Pumping System Assessment at a California Tomato Processing Facility

This report provides results from a US Department of Energy (DOE) Pump Energy Systems Assessment (ESA) conducted by DOE Qualified Specialists. The ESA includes an inventory of all motors, pumps, and a steam turbine used to power process water in the facility. A Pump Calculator is developed to evaluate the energy demand per unit of water and establish Water Energy Intensity (WEi) ratios. The Pump Calculator is used to identify pumping systems in need of performance improvements. This ESA Report supports research conducted by CIFAR to pilot the Water Energy Nexus (WEN) at a California tomato processing facility.

II. INDUSTRIAL WATER ENERGY NEXUS

CIFAR has developed a Water-Energy Nexus (WEN) Assessment methodology to evaluate industrial water conservation opportunities and energy efficiency measures. The adoption of these recommendations can deliver economic benefits from reduced groundwater pumping and lower wastewater surcharges, as well as environmental benefits by preserving ground water resources, lower air pollution emissions and reduced wastewater discharge. The emission reduction benefits available from implementing recommendations can also help industrial facilities comply with California’s Cap and Trade program.

Industrial Water Energy Nexus Assessment: Campbell Soup Tomato Processing Facility

This paper documents the results from a Water Energy Nexus (WEN) assessment conducted at a Campbell Soup California tomato processing facility. The WEN assessment calculates the amount of direct and embedded energy consumed in process water. The assessment results are used to identify energy efficiency measures, improved operational efficiencies, and the potential to generate combined heat and power resources. These recommendations deliver economic benefits from reduced energy costs and significant environmental benefits from the preservation of ground water resources, lower air pollution emissions and reduced wastewater discharge. A baseline was developed to account for the water energy intensity of processing tomatoes at this facility. This baseline will be used to compare the economic and environmental benefits from the adoption of recommended efficiency measures.

Water Energy Assessments: Technical Support

The California Institute of Food and Agricultural Research (CIFAR) at the University of California Davis (UCD), provides technical expertise to food and beverage processing facilities conducting Water Energy Nexus Assessments. To provide these services, CIFAR integrates knowledge from UC Davis professors and field specialist along with the experience of senior engineer sub-contractors who are DOE Qualified Specialists in industrial process system evaluations. This brochure provides a template of CIFAR’s Industrial Assessment services.

III. BIOENERGY

Organic Residue Assessments

CIFAR conducts food and beverage industry residue assessments and calculates the technical potential to generate bioenergy resources. CIFAR integrates the results from the Steam and WEN Assessments to discover and implement synergistic system improvements.

California Food Processing Industry Organic Residue Assessment

This California Biomass Collaborative document analyzes results from an organic residue assessment of the California food processing industry. The objective of the research was to estimate the amount of wastewater and solid residues available and calculate the potential energy these resources can generate. Food processor sectors investigated included: fruit and vegetable canneries, dehydrated and fresh/frozen fruit and vegetable processors, dairy creameries, wineries, meat processors and almond and walnut processors.

IV. ENERGY MANAGEMENT SYSTEMS

California Food Processing Industry Wastewater Demonstration Project

This project established and tested a methodology for (1) gathering baseline energy and environmental data at an industrial food-processing plant and (2) using the data to analyze energy efficiency, demand response, daily peak load management, and environmental management opportunities at the plant. The Phase I goals were to demonstrate the measurement and interrelationship of electricity demand, electricity usage, and water quality metrics and to estimate the associated CO2 emissions.

ISO 50001 Energy Management Standard

The Department of Energy (DOE) supports the ISO 50001 Standard as a proven approach for U.S. industrial facilities to plan, manage, measure, and continually improve energy performance. This standard from the International Organization for Standardization (ISO) provides an internationally recognized framework for organizations to voluntarily implement an energy management system.

V. CONTINUOUS ENERGY IMPROVEMENT (CEI)

CIFAR collaborates with California’s Investor Owned Utility (IOUs) companies delivering CEI services to food and beverage processing facilities. CIFAR introduces the CEI concept to facility managers aware of the conservation and efficiency opportunities identified by the ESAs and WEN Assessments. The CEI methodology can help managers plan and execute adoption.

2. Biomass: Bioprocessing to Fuels, Chemicals and Materials

CIFAR has been engaged in research, forums, and expert panels in this area. Products include the development of microbial and enzyme systems for tailoring the conversion of rice straw to products, including mixed carbohydrates, lactic acid, ethyl lactate and ethanol; a document that lists the capabilities in the western region for bio-based products (October 2003), a seminar series as part of the CA&ES Bio-based Initiative: Products and Processes, and a participant in the DOE strategic team in the area of cell wall deconstruction.

CIFAR has received support from the U.S. Department of Energy and its National Renewable Energy Laboratory, Pacific Northwest National Laboratory, Argonne National Laboratory, the California Energy Commission, and UC Davis College of Agricultural and Environmental Sciences. CIFAR partners with UC Davis researchers and supports the California Biomass Collaborative and the Institute of Transportation Studies.

International projects and guidance comes from its collaborators in countries such as China (Fuzhou University, Zhejiang University, Southern Yangtze University) and India (Mr. Ammi Armanath serves as a CIFAR advisor in this area).

3. Food for Health and Well-Being

CIFAR is engaged in assessing the opportunities in this area, compiling UC Davis research areas and inventions, organizing forums and conferences, and co-sponsoring student business plan competitions. Mr. Allen Bah brings his international experience and contacts to assist in this effort.